Business Cases

Examples of where our solutions have been successfully implemented.

Foundry - Waterloo QC , Canada

Industry Challenge

- Old machinery in operation

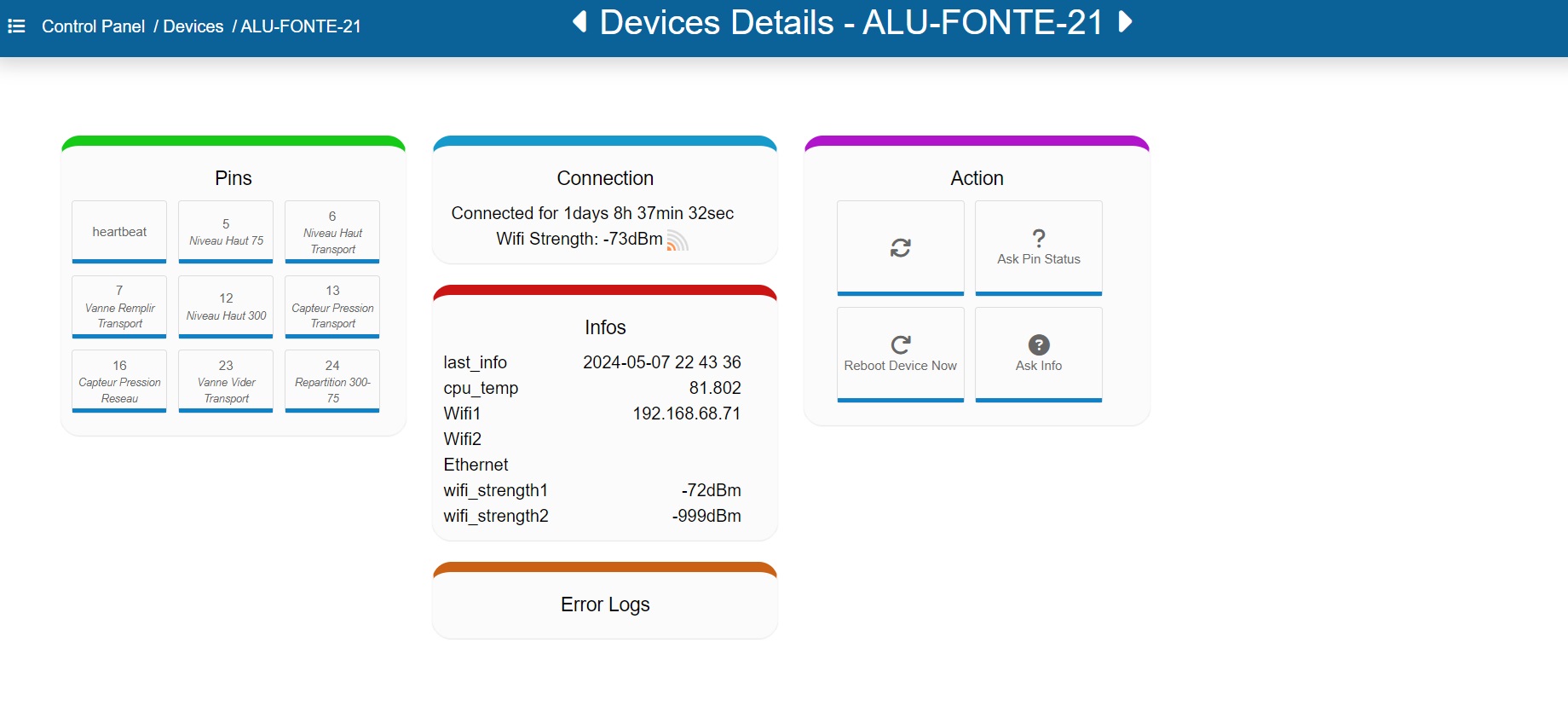

- Extremely dusty environment impacting sensor performance

- No affordable sensors capable of accurately measuring the fill level in sand tanks

- Frequent risk of running out of sand due to sensor malfunctions

- Furnace pulling excessive current, risking a factory-wide power trip

Solution Provided

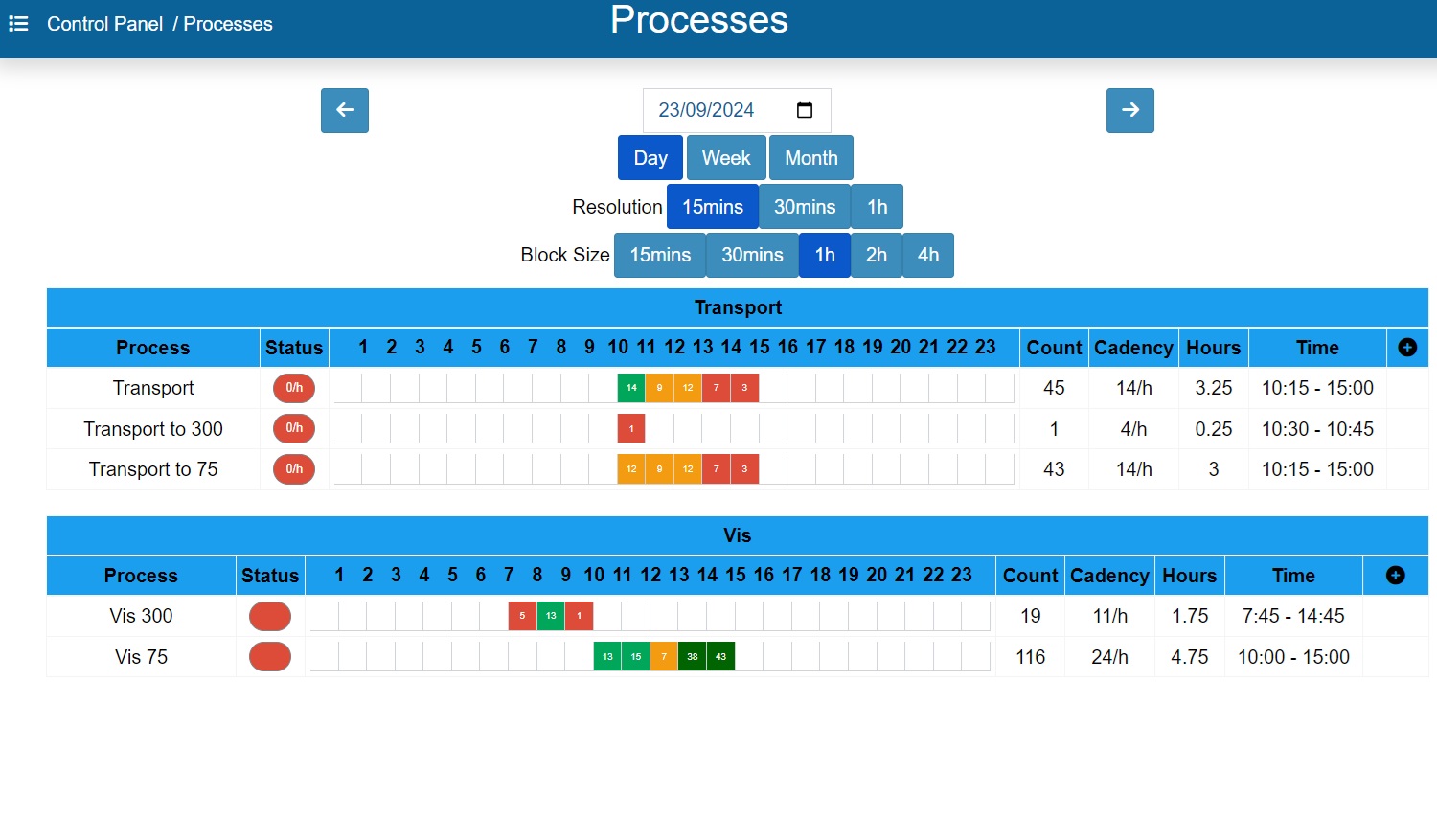

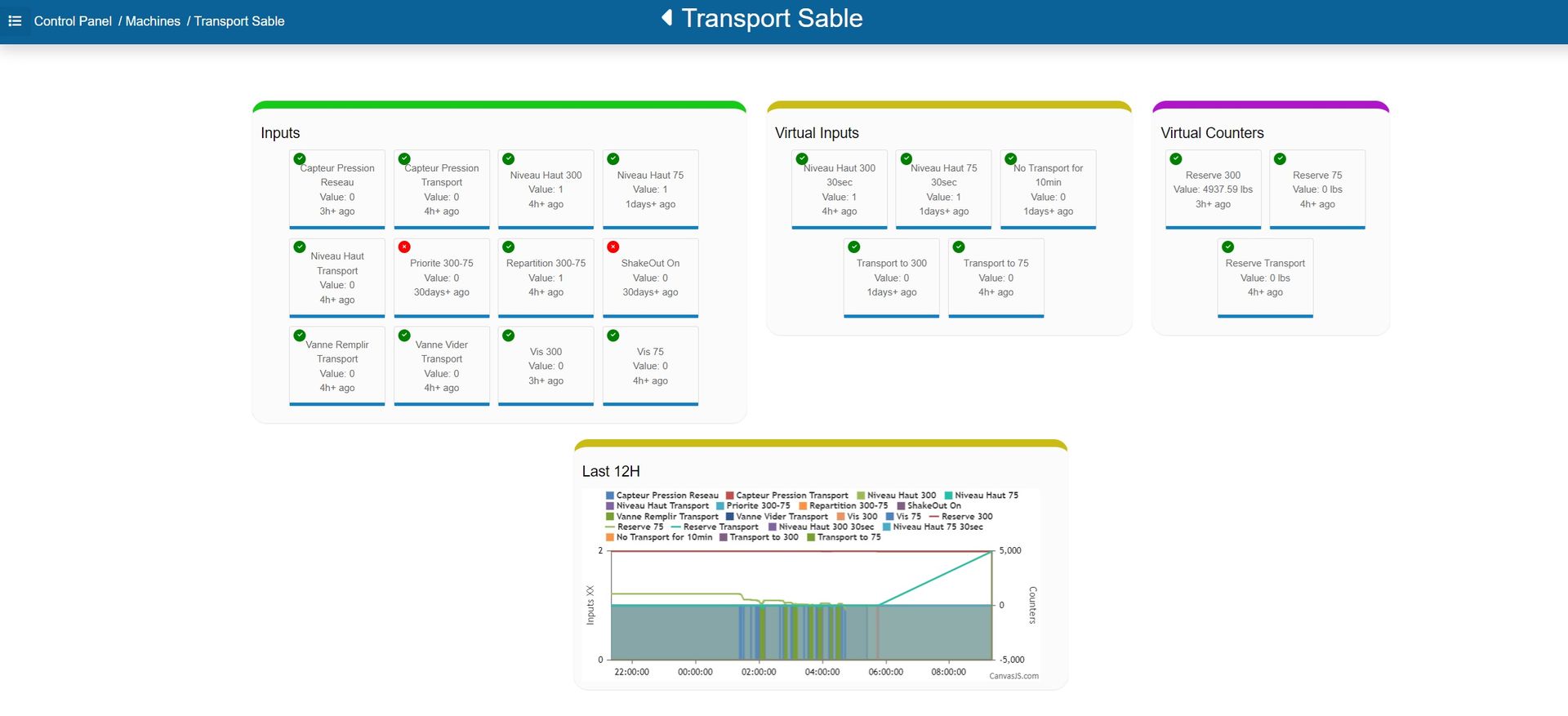

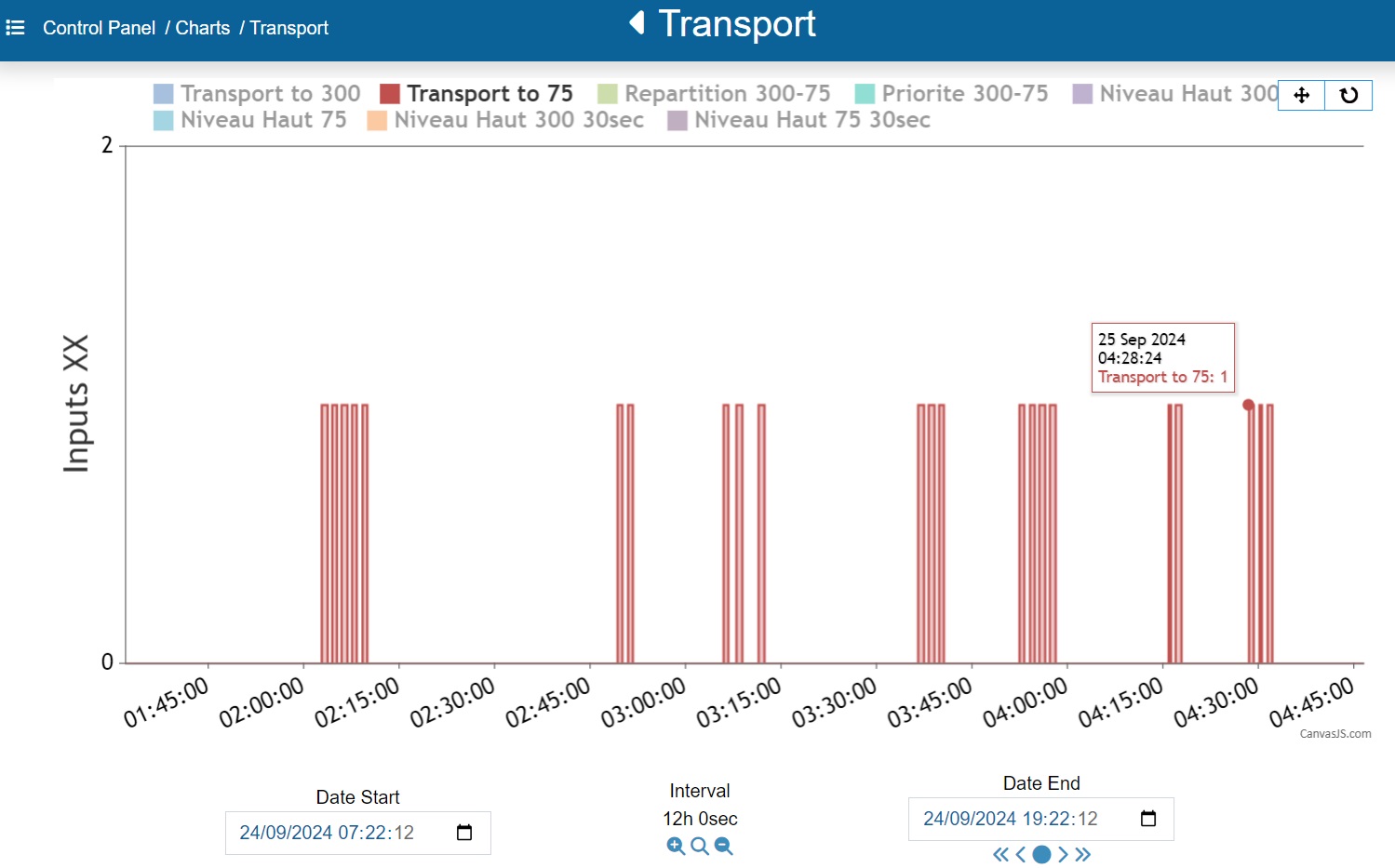

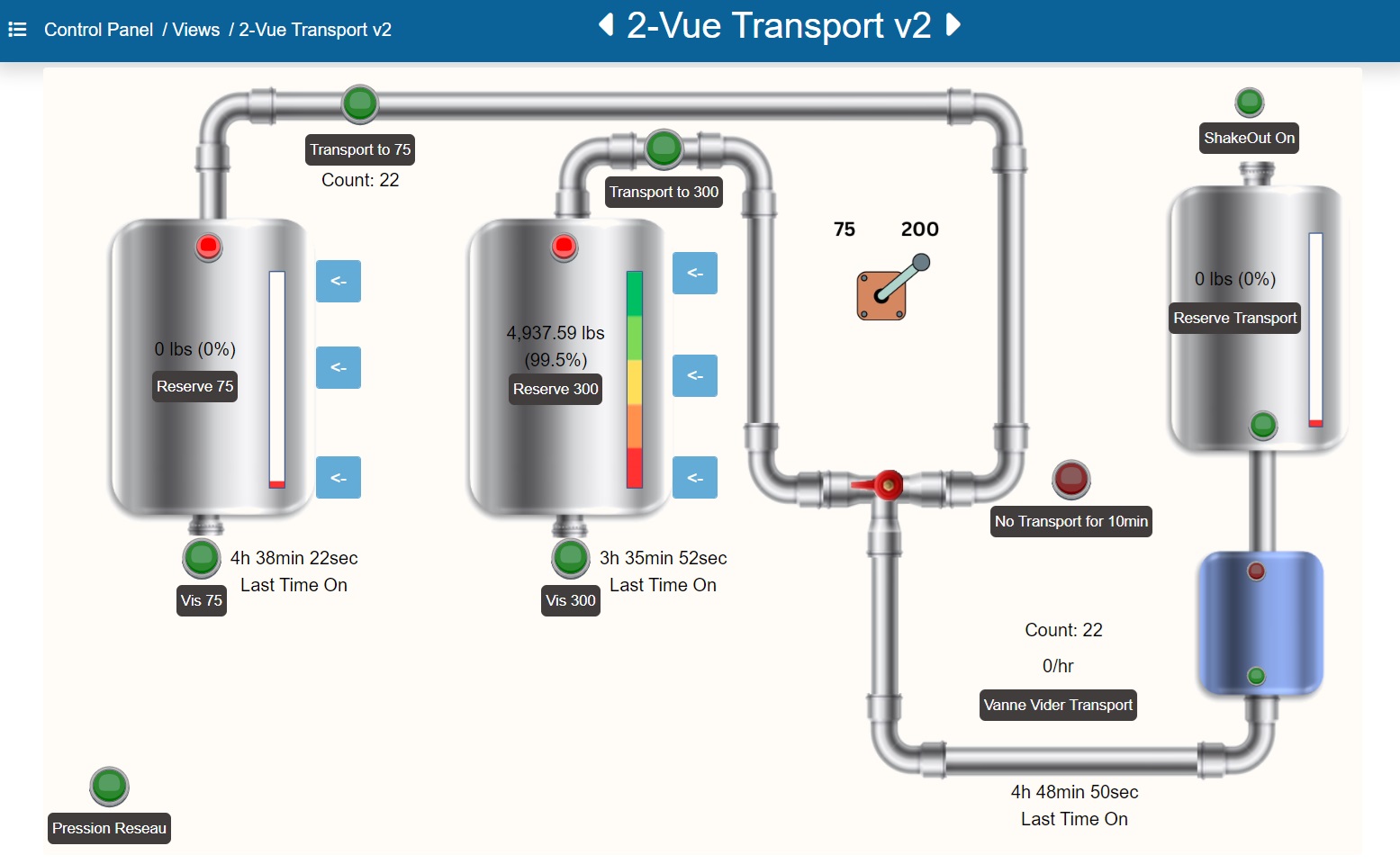

- Monitored the flow of sand being transported to and from the tank.

- Constant estimation of sand levels to ensure proactive monitoring

- Alerts sent to operators before sand levels become critical

- Monitoring of furnace current draw, with alerts before power reaches dangerous levels

Key Benefits

Real-Time Monitoring

- Live view of production KPI

- Remove the need for PPE-heavy factory visits to supervise production.

- Daily/weekly/monthly production review

Accessible Anywhere

Data is accessible in real time:

- on the leading hand’s tablet,

- in the general manager’s office,

- on the phone of key personnel

Improved Reliability

- Remove production stoppage due to sand shortage.

- Prevents unplanned factory wide power shutdowns.

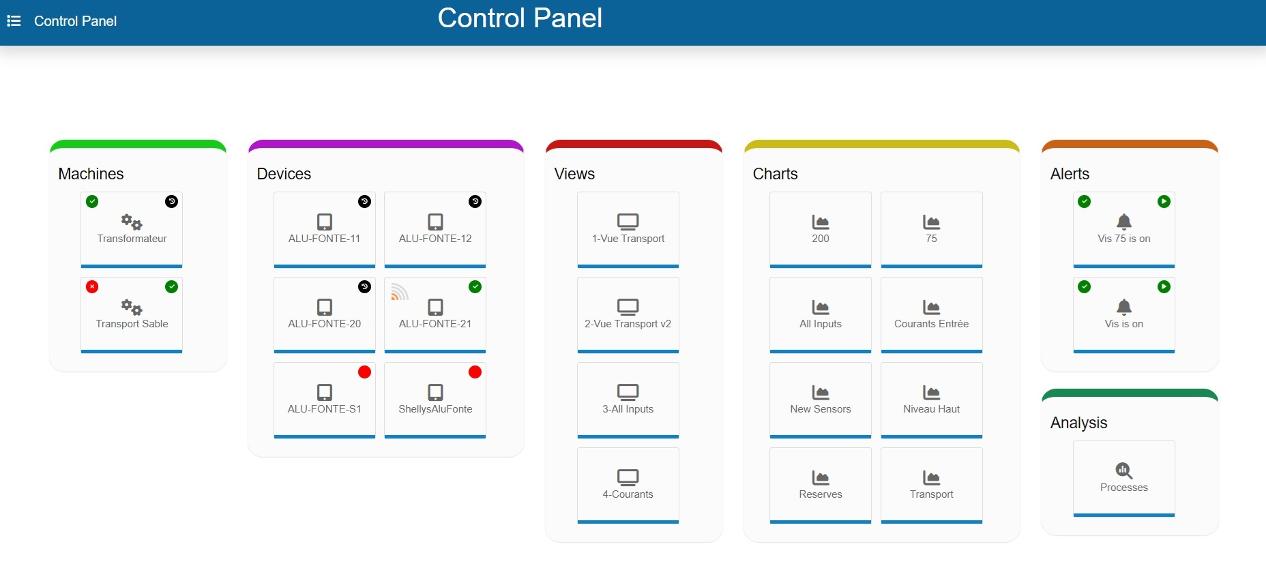

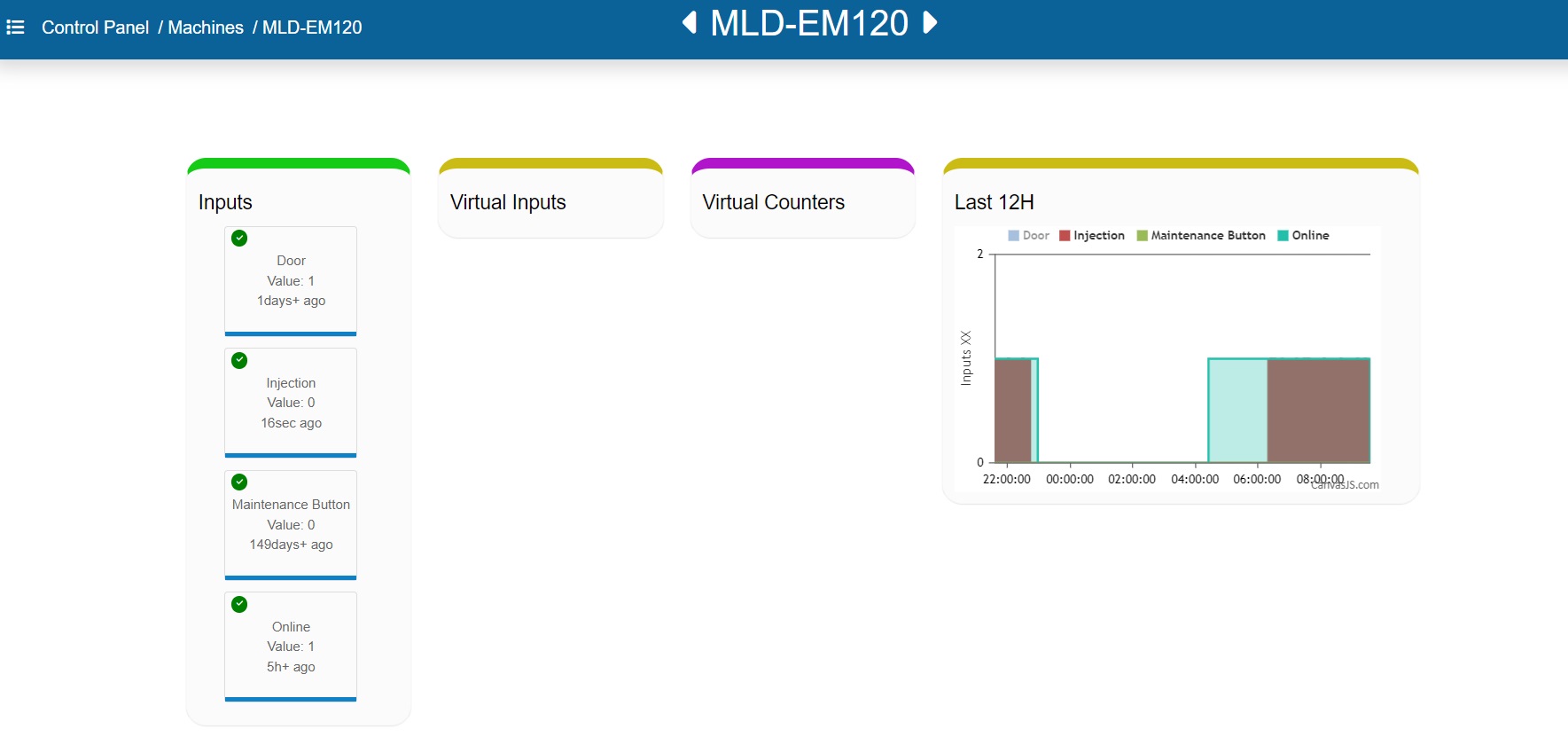

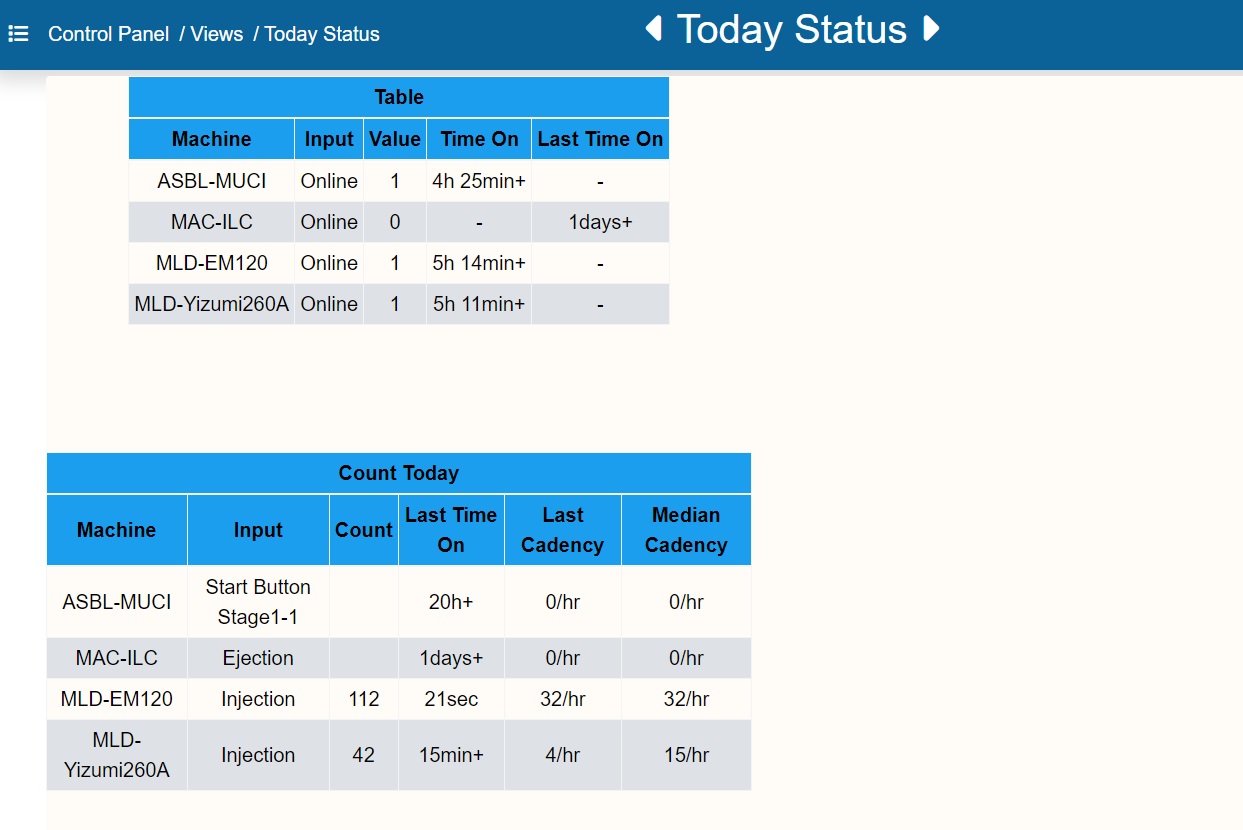

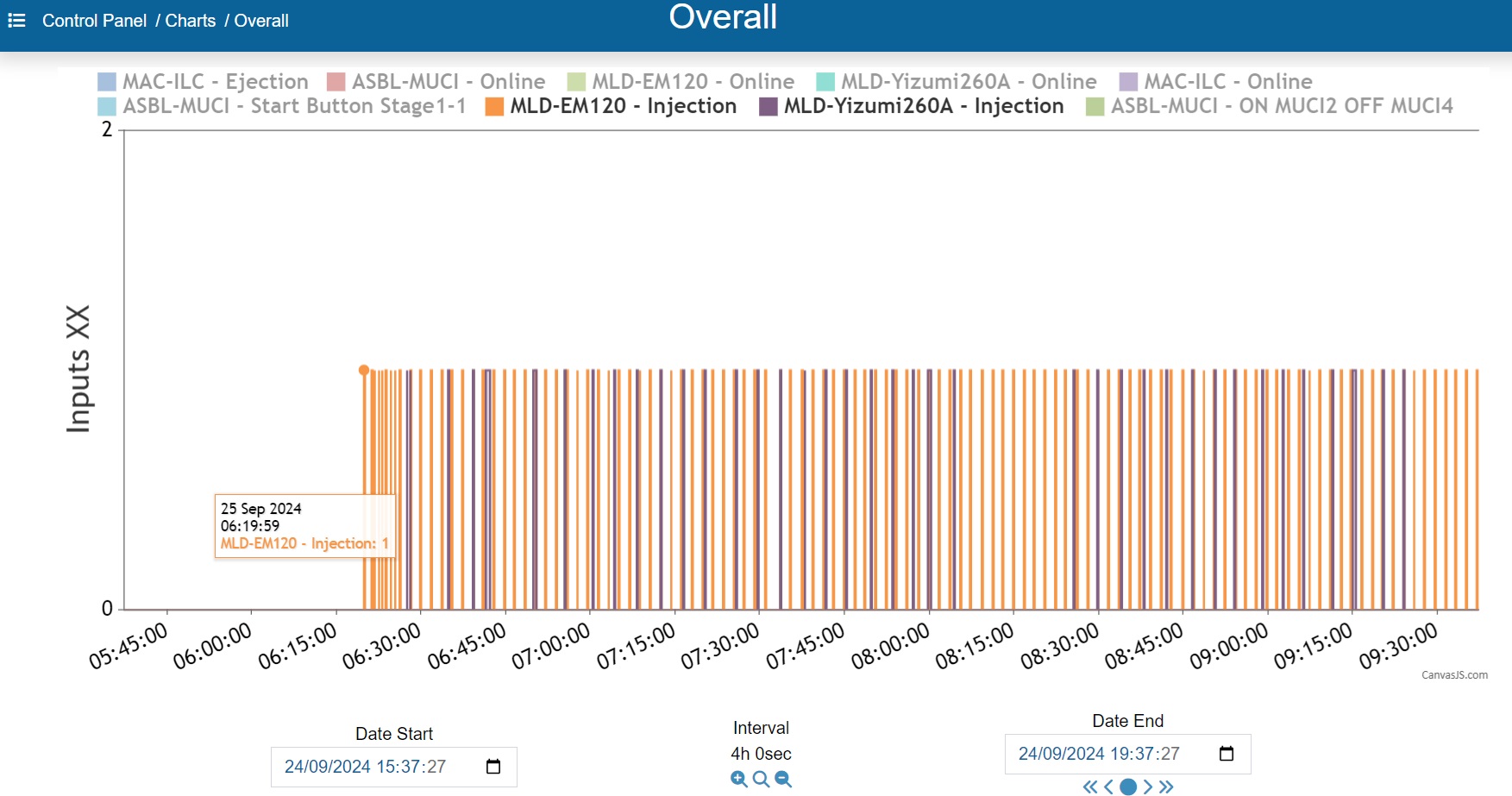

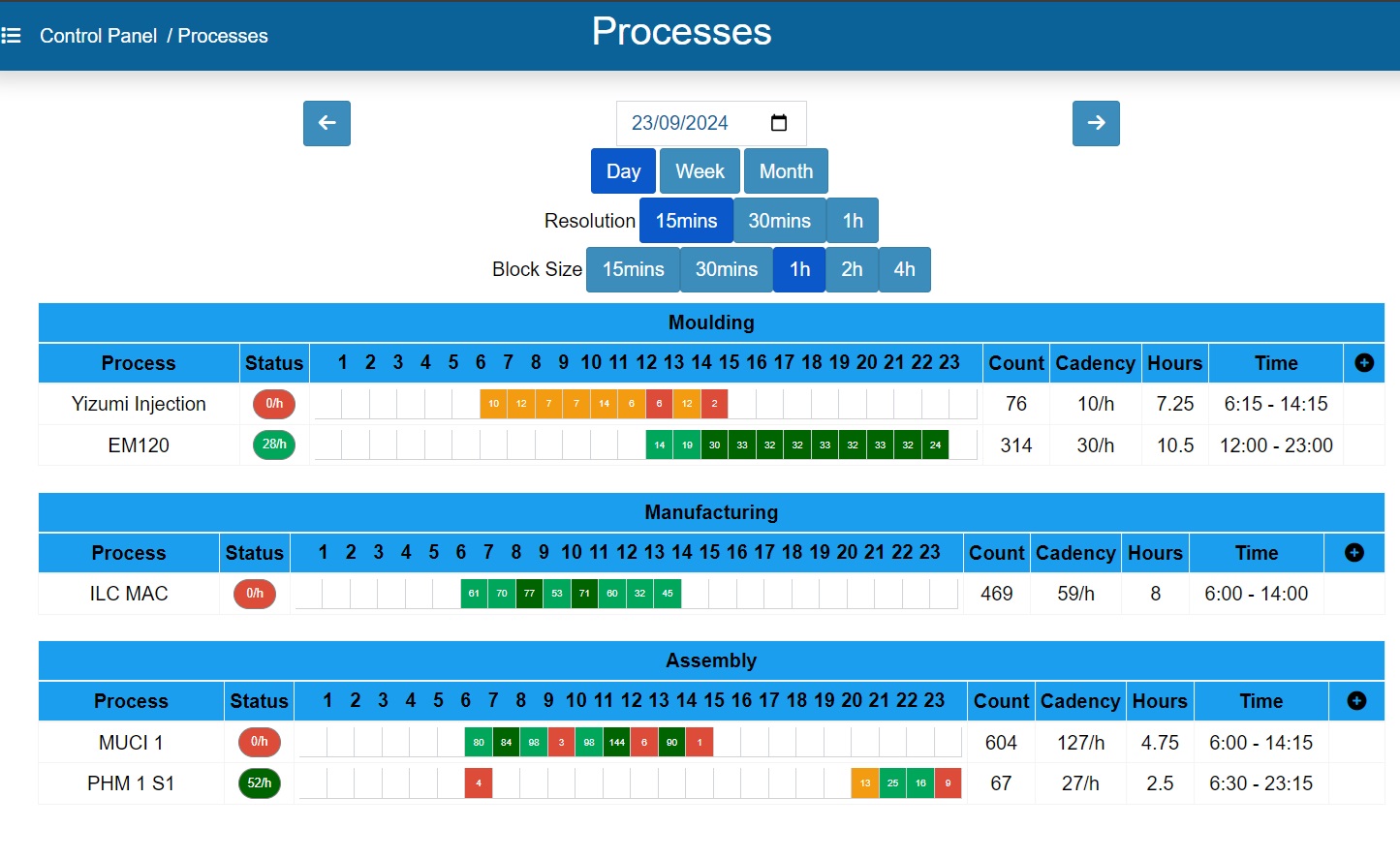

Screenshots

Electrical Connector Manufacturer - Gold Coast, Australia

Industry Challenge

- Need to optimise production to remain competitive against low-cost competitors

- Understand machine capacity to determine if production demands can be met

- Track changes and quantify improvements from optimisation projects

- Visualise production flow and identify stoppages quickly to respond faster

Solution Provided

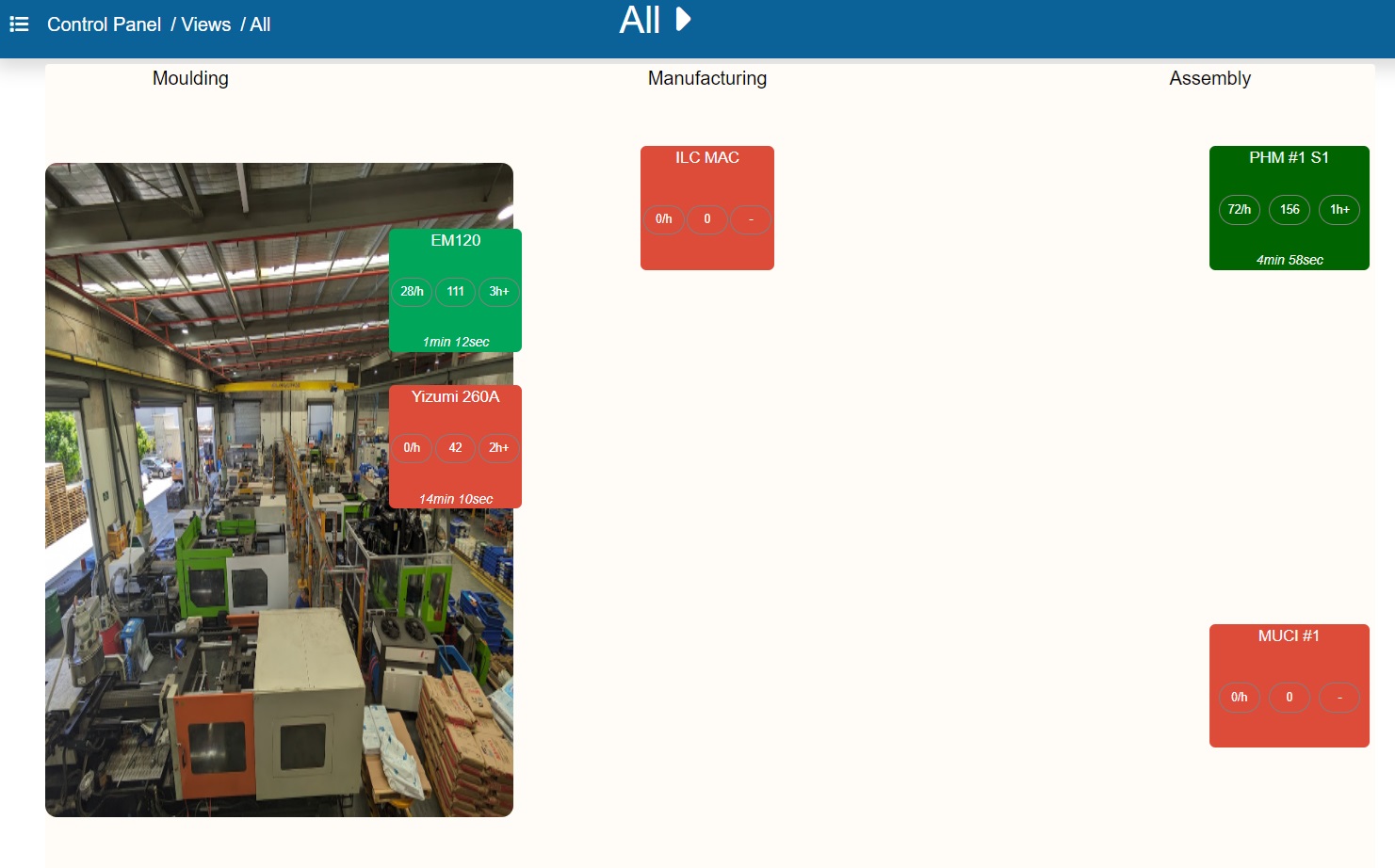

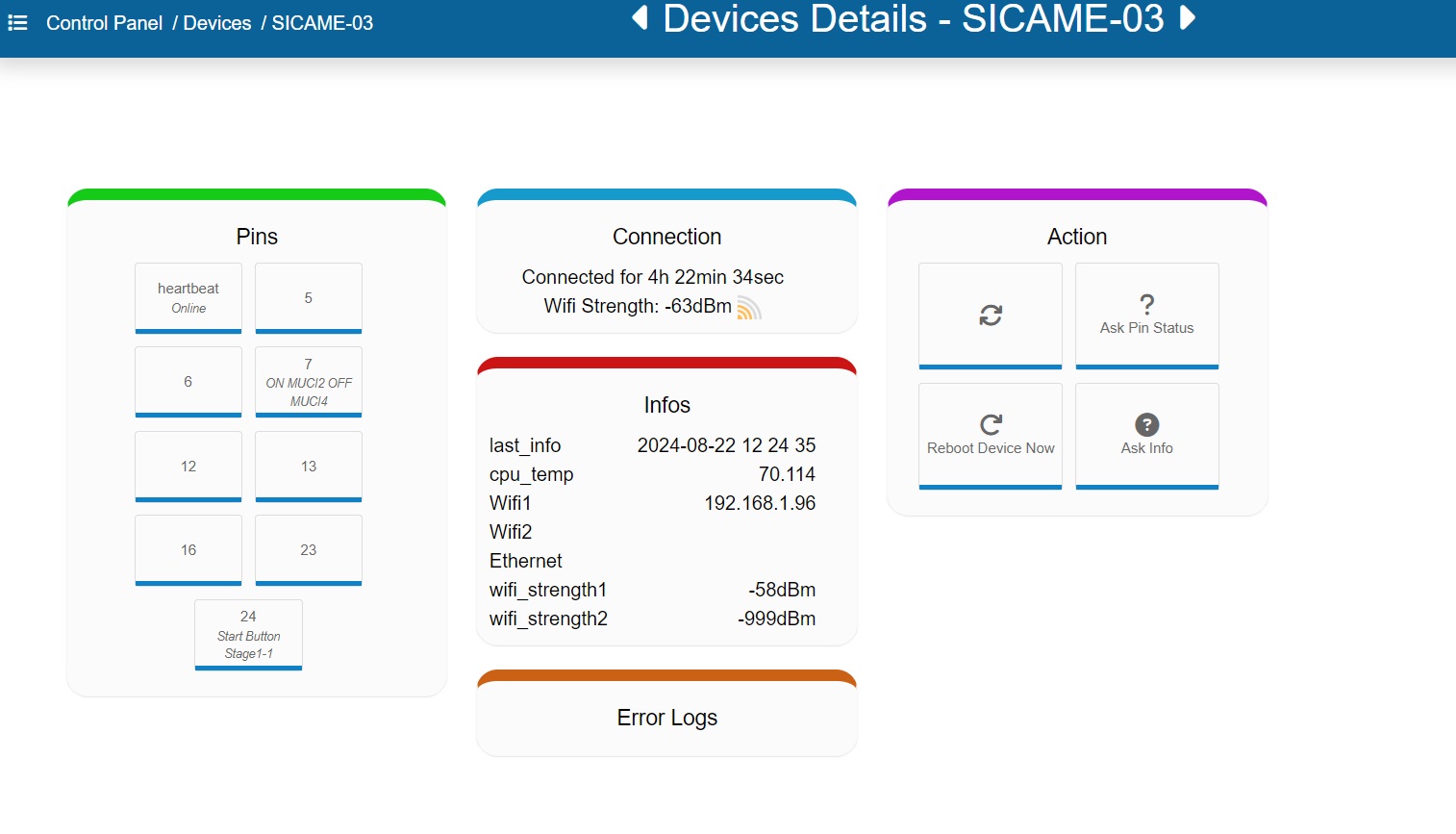

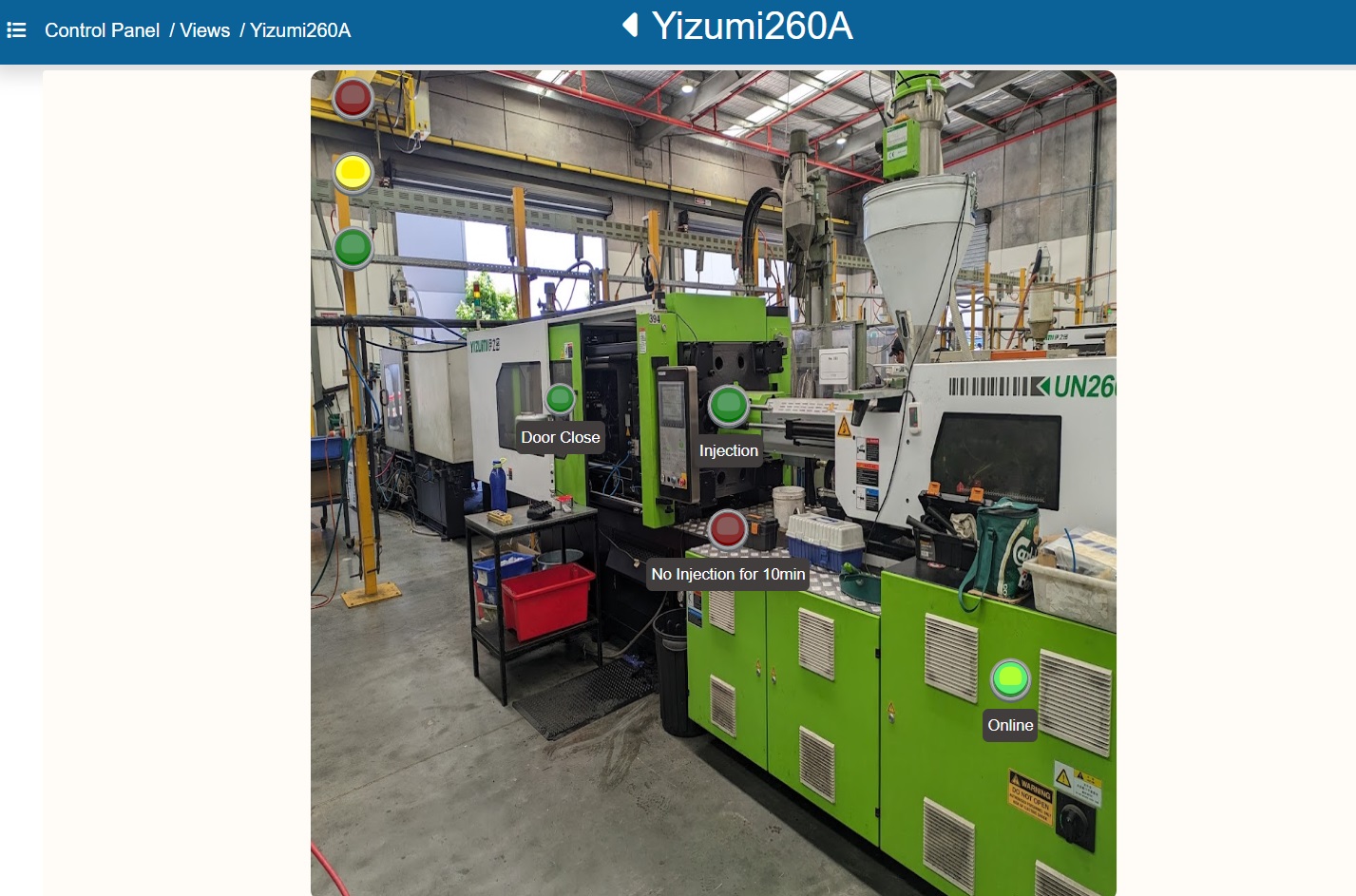

- Installed trackers in machines to monitor parts produced and machine operations

- Measured cycle time and machine operating time for better performance insights

- Developed dashboards to facilitate communication between operators and production managers

- Automated reporting system created for production managers to easily track production metrics

Key Benefits

Real-Time Monitoring

- Live view of production KPI

- View of machine capacity, ensuring that production demands can be met or machine is under-utilised.

- Automated reporting, streamlining the monitoring of production performance.

Enhanced Competitiveness

- Improved production efficiency to keep up with low-cost foreign competitors.

- Tracking and quantification of optimisation projects' impact on production.

- Quantification of production shortage cost

Proactive Maintenance

- Visualised production flow with stoppage alerts, enabling faster responses to any issues